Or maybe it's re-rope sash, or restring windows, or re-weight with sash cord? No matter, sit back, buckle in, and get ready for a riveting blog post about restoring antique windows! I doesn't get much more exciting. (I'm lying, it can only get more exciting.)

Antique double hung windows are beautiful, there's no doubt about it. I didn't realize this for many years, but after buying our home and falling in love with old homes, the old sash are one of the four truly enchanting elements of architecture I feel set an older home apart from the pack (the other three are their staircases, period doors & door hardware, and moulding/millwork). When I'm drooling over a magazine house, a real estate listing that I can't afford, or a falling down house with "good bones" I just wish I could spend another decade saving, these are some of the primary aspects I immediately look for. And if any of these homes are lacking any or all of these details...they're dead to me.

While I'm an equal opportunity lover of old windows, the majority of my restoration efforts are geared toward the style of windows in our home -- rope and pulley double hung sash. This is primarily because they're the ones with which I'm most familiar and comfortable.

Our style of windows are actually very common in the era of our 1880s home, and in about 50 years in either direction. The style is fairly straight forward and contains two sash, an upper and lower, which are movable and counter balanced by large weights that live in cavities beyond the jambs of the window frame. When the sash are raised or lowered, the sash weights, attached to the sash by cording, travel up and down in the hollow channels, allowing the windows to stay open without any other props or stays. It's a very functional system that works quite well. However, one of the common plights of the rope and pulley double hung sash comes by way of frayed and broken ropes (or sash cord).

After years of use and abuse, these weight cords begin to wear away. They're often painted by careless contractors, snagged by nails or hangers added in incorrect places, rotted by moisture, or just plain pulled on by one too many people. After they've had enough, they give up.

The best news about these weight cords is they're rather easily replaced, but there are a few tricks I've picked up along the way that makes the process much easier.

Replacement Cord Material

The first step in replacing sash cord is to determine the material you'll use in the project. There are actually several different options out there for you, from "in kind" to "long lasting." The truth is, as far as I've been led to believe, each is acceptable and it just comes down to preference.

Typically, you'll consider replacing your rope either with another rope, or replacing it with sash chain.

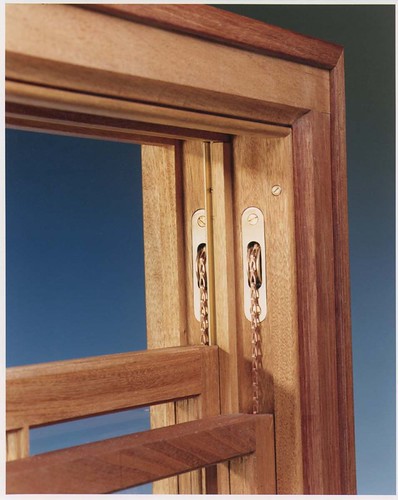

I actually have a bag of sash chain in our basement as I had planned on using it in the first window I needed to restore, but I ran into a snag. No, not a snag in the project, and aesthetics snag. I saw the chains installed in another home's windows.

Photo Credit: Wood Window Workshop

I don't know why, but the chains just don't do it for me. When I saw them they looked wrong for our house, and when I opened the window and heard the metal on metal clank of the chain rolling over the pulley, that killed it for me. I thought to myself, "I know the original cord in our windows is, well, original, so why replace it with a different material? It had already lasted nearly 125 years."

So my search began for suitable sash cord to replace our broken and worn cord.

First I found the standard braided laundry line you can buy at most big box home improvement stores. The cord is all white with a nylon/cotton core and is the right size for the sash cord. I thought I had found the perfect replacement, so I went ahead and bought 100' of it and replaced the rope in our bedroom windows.

I was feeling good about my accomplishment, but there was always this little voice in the back of my head saying "that rope wasn't perfect, it didn't look identical to the old stuff. The old stuff had little red dots in it."

I shut that little voice out of my head until one day, when I was looking around online, and came across SRS Hardware, a company dedicated to the historic preservation and recreation of true divided light windows and wood storms. They have a great collection of necessities for people restoring windows, including the elusive Sarco glazing. In their list of products they had EXACTLY what I was looking for...and I mean exact!

They carry a type of sash cord that is made by the same manufacturer of sash cord that was used on our original windows. Same small company, same design, same little red dot. It was a moment of pure, unadulterated excitement when I discovered this source.

It was also a roughly this moment when I once again had it reinforced that I'm an absolutely huge nerd that is able to get tremendous excitement from the most mundane and lame things. Twelve year old me, you grow up to be super lame.

I immediately ordered 100' to use on all of our remaining windows (then I started fighting the internal voice about replacing it on the windows I'd already done).

Upper Sash Restring

With the sash cord in hand I started my restring process with all of the cords, weights, and sash out of the window, and the weather stripping in place. Just look at it, 125 year old compared to new!

If you're following along and doing this project on your own, there are a few minor differences if you haven't completely torn apart your window like I did, but all of the principles still apply.

My first step is to feed the cord trough the pulleys. The upper sash is a little harder than the lower due to the fact the pulley must already be in place since it needs to be there before installing the weather stripping.

However, I only placed the upper sash pulley at this point, leaving the lower sash pulley out for the time being. This allows me to begin by stringing the cord through the first pulley and then grabbing it through the other pulley hole.

At that point I tape a large drill bit to the end of the sash cord and drop it down inside the cavity until I can grab it through the lower opening.

Now, I haven't mentioned length yet, and that's for good reason. Each window has its own unique measurements, and you'll need to determine correct length as you go. I like to just feed the cord from the rolled up bag before I ever make my first cut.

It's important to remember that the correct function of the sash actually determines the length, and the length of the weight and where the rope attaches to the window plays a role. The rope needs to be long enough to allow the sash to be fully lowered without the weight or knot running into the pulley, and short enough to allow the windows to be fully raised without having the weight hit bottom. You also need to account for the necessary knots you'll need to tie at either ends. This is why I like to figure out length as I go, rather than trying to come up with a formula.

My next step is to tie the new sash cord to the old weight. I grab the weight that I labelled for the upper sash and begin preparing the knot. My goal is to tie a knot that's secure and as much like the original knot as possible. There's a reason why it lasted 125 years. Here's an example of the old knot...

...And here's the completed and new knot, ready for years of service.

Tying the knot is just three easy steps.

Step 1: Run the cord through the top of the weight.

Step 2: Loop the cord around the back of the in-feed piece of cord.

Step 3: Loop the end of the cord back around to the front and through the loop, pulling the knot tight.

With the knot tightly tied, tuck the weight back in its pocket and move onto the next step.

The next step in proper measurement is critical and will make or break your restring. With the weight back in the pocket, grab the upper sash and make pencil mark of where the top of the hole for the rope knot sits on the side of the sash.

Lift the sash up into the window in the location where it will sit when fully closed and use a pencil to mark the jamb where the pencil mark on the sash is. This will tell you where the upper extent of the sash cord knot should sit.

Remove the sash from the window and place the sash back where you were storing it. Then grab the sash cord and pull down until the sash weight lifts up about one inch from the bottom of the weight cavity floor. Full tension from the weight should be on the rope and you should be able to move it freely.

With the weight one inch off the base, use your pencil to mark the rope with two small marks. The first mark is at the line you made on the jamb for the sash knot hole and the second is at the based of the pulley, right where the rope would begin to wrap around the pulley wheel.

These two marks are your primary points of reference for where the rope should end up once fully installed.

Now you can grab your scissors, as it's time to cut. To cut your rope, locate the mark for the sash knot hole and then cut about one foot lower, giving yourself plenty of excess.

Next, tie a very tight knot that is small enough to fit in your sash knot hole, and try to place that knot directly on the middle of the pencil mark. I typically do a simple pretzel knot that I tie as snug as I can. The most important thing is for the knot to be no bigger than the hole allows, i.e. it can't be spilling over or too thick. Test fit your knot, and once you're happy, cut your cord about an inch below the end of your knot.

Attaching the sash cord to the sash is not necessarily a two person job, but two people makes it a lot easier. That being said, I've done this with by myself several times, and I've only almost fallen out of the window once.

The easiest way to do this is to have one person hold the sash while another puts the rope in place.

The original rope installed in our windows was tacked in place by several nails through the sash's rope channel. While this was effective, I want to be able to easily remove the sash in the future when I restore them.

Rather than using nails again, I opt to use a screw, as I can place and remove it when necessary. It feels like I'm cheating a little but, but I really feel like it works quite well. At this point in just using a simple 1-1/4" drywall screw since it's purely temporary.

When I actually put in the sash after restoration, I'll use a #8 stainless slot head screw.

Place the screw right through the middle of the knot and into the sash, but don't sink the screw all of the way. Just place it deep enough to be secure.

Still holding the sash, grab the other rope and place it in the same manner, then slide the upper sash into place.

Take a step back and admire your work. You've just restrung half of your window!

Lower Sash Restring

The lower sash follows a very similar overall process, save for a few small details.

The first change is in how you run the sash cord. Since the pulley doesn't need to be installed for weather stripping, you can leave it out until after you've run the cord, making the whole process of getting your cord in place much simpler. This time, just put the cord through your sash pulley while it's out, then tape a drill bit to the end of the rope and feed it through the opening.

Once the drill bit hits bottom, run the pulley up the cord and put it in place.

Note: If you're doing this whole process but you're not removing your pulleys, you can use a smaller weight (smaller drill bit?) that will fit through the pulley's opening.

Like with the upper sash, it's time to tie on the weights. In our windows the weights for the upper sash are larger and heavier than the lower. It makes sense, since their job is to keep the sash up rather than to simply counter balance as it's raised. So it's important to take note to ensure you're installing the correct weight for the correct sash.

Once I had the sash weight good and secure, I started working on the length of the cord I'd need. Similar to the upper sash, the key here is to get the length of the rope right, but using an opposing approach. With the lower sash you need to be sure that the window can be fully raised without the weight impacting the bottom of the cavity, but it needs to be able to be closed without the knot or weight running into the pulley.

So I grab the lower sash, make note of the knot hole along the side, and hold it in place in the window opening. In this case, like the upper sash, I hold the sash in place near the top of the window in it's fully open position. Once I'm happy with it, I mark the top of the hole on the jamb.

With the jamb marked, I grab the cord and pull down (pulling the weight up) until the weight is just slightly above the base of the window frame. This will be where the weight rests when the window is fully open. I find it's easier to measure the cord length for the lower sash fully open rather than fully closed.

Finally, make a pencil mark on the rope where you marked the jamb for the knot hole location.

In the same manner as with the upper sash, cut the cord about a foot longer than the pencil mark and tie a knot that stops at the line.

Once this was done on both sides, I had my ropes in place and was nearing completion. Letting go of the lower sash ropes should cause the knot to rest against the upper portion of the pulley.

Attaching the ropes to the sash in the same manner as I did on the upper sash and we've for a fully functional window!

It's important to note that I skipped the step of reinstalling the window's parting bead and sash stops as I intend to take the sash out again to strip and reglaze them. I'll tell you one thing for sure, those parting beads sure do offer a tremendous amount of draft reduction. Our windows are super drafty without them.

There you have it, a full (and frightfully boring) step by step guide on replacing your weight and pulley double hung window's sash cords. I was once rather intimidated by this whole project, but now that I've done it on several windows, it's a completely bearable project that I'm excited to undertake on the remaining original windows of our home.

Now that the sash are restrung we have a final few major steps left before these windows can be called fully finished. Lets recap from our window restoration checklist.

- Disassembly

- Frame Paint Removal

- Frame/Component Repair

- Weather Stripping

- Restring Sash Cord

- Storm Window Installation

- Sash Removal and Repair (this is a multi-step one on its own)

What do you think? Is this something you're going to put to use in your home? Does it seem manageable to you, or extremely involved and simply too much work?

![]()

![]()